Deeptech factory

Carbon-negative Hydrogen

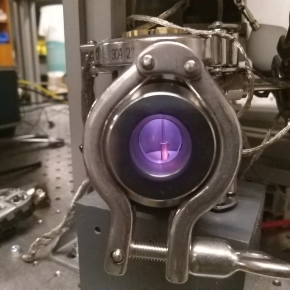

Spark is pioneering a new way to produce hydrogen: methane plasmalysis. Our patented technology, unique worldwide, converts (bio)methane into hydrogen and valuable carbon black, with zero CO2 emissions and consuming 5x less electricity than water electrolysis.

TECHNO / PRODUCTS

TECHNO / PRODUCTS

Our methane plasmalysis technology uses nanopulsed cold plasma to convert (bio)methane into hydrogen and carbon black. This results in a a zero or negative carbon footprint, depending on the input, with very low power consumption. Spark’s nanopulses are a patented technology, unique worldwide, which enables plasma temperature to be controlled to achieve the optimum combination of rapid reaction and low heat loss. Temperature control enables us to target a power consumption of 10 kWhe/kg H2, i.e. 5x less than water electrolysis and 2 to 3x less than thermal plasmalysis. Spark’s nanopulsed cold plasma is the most suitable technology for efficient, modular and decentralized plasmalysis.

PORTEFEUILLE PRODUITS

APPLICATIONS

APPLICATIONS

Spark offers competitive, decarbonized hydrogen produced directly on the consumption site, as a replacement for grey hydrogen delivered for current consumers and as a substitute for natural gas to decarbonize industrial heat. Thanks to its modular, decentralized system, Spark avoids the economic and environmental costs associated with the complex and costly transportation of hydrogen (70% of the total cost).

Spark also handles the management and resale of the co-produced carbon black, a precious material with versatile properties, essential to many industries (tires, batteries, building materials, pigments…). Spark’s (bio)carbon replaces the carbon black produced using current processes that emit high levels of CO2.

BENEFITS

BENEFITS

– Zero CO2 emissions (carbon-negative with biomethane)

– Low power consumption (5x less than water electrolysis)

– 100% product recovery: decarbonized hydrogen for greener industry + clean carbon black for greener materials.

– Direct on-site production to avoid the economic and environmental costs of transporting hydrogen.